Here’s a quick post of a recent restoration of a Phoebus 625. This was one of a pair I bought on eBay as a two-stove Buy-It-Now package deal. Both stoves seemed mostly complete though this one of the pair was missing it’s spindle knob. And, of the two, this one came in a stuff sack while the other sported an actual tin.

Here are some shots of the process. click image to enlarge

- parts on disassembly

- tank

- cleaned and stripped parts

- polishing pot legs

The tank was stripped and glass bead blasted to provide a good surface for new paint. All the parts were degreased and cleaned. The pot supports were polished up on my buffing wheels. The tank was sprayed with VHT Engine Paint SP402 Burnt Copper. I like this color because it’s about the closest rattle can color to the original, plus it’s rated to 650 deg F (240 deg C) in heat resistance. Well-cured for three to four weeks, it’s pretty much proof to Coleman fuel.

The windshield was glass bead blasted and then painted with VHT “Flame Proof” SP998 Cast Iron. This is a paint rated even more heat resistant at 2000 deg F (1100 deg C). Unlike some of the other VHT Flame Proof paints, this one doesn’t seem to “brown” as much with exposure to direct flame. Good idea as the wind shield gets a lot of that from the preheat flames.

I added a brass preheat pan between the tank riser and the burner base so that the preheat alcohol will stay off the tank. Here’s how it turned out. click image to enlarge

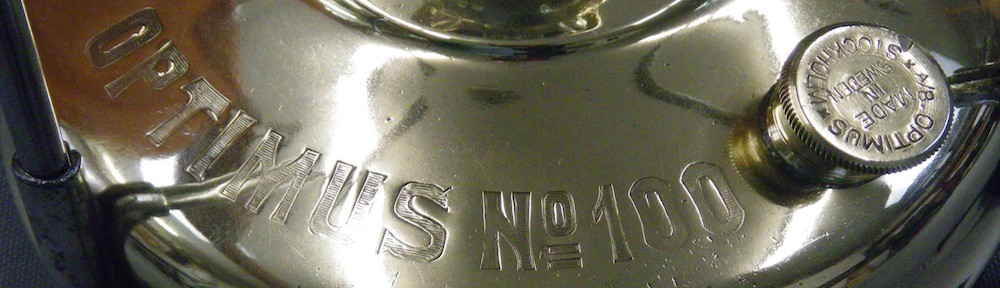

- completed resto

- VHT SP402 paint color

- VHT SP998 paint on wind shield

- simmer