Hi BD

I want to fix my old stove and I need to get the NRV out of the pump tube to replace the old rotten pip. I tried to buy one of those NRV wrenches from S. Korea and, then, from the UK, but those sellers don’t seem to be able to ship overseas due to COVID-19. Can you tell me the dimensions of the NRV head, please?

TIA, Old Stove Guy

Hi, Old Stove Guy

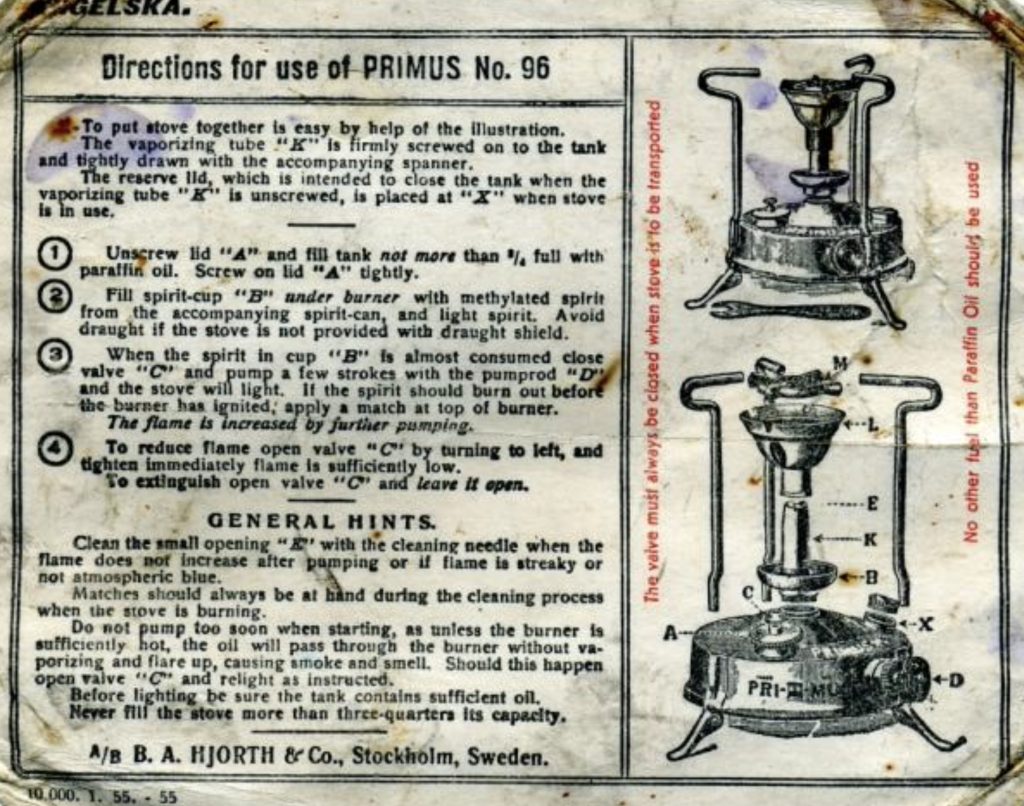

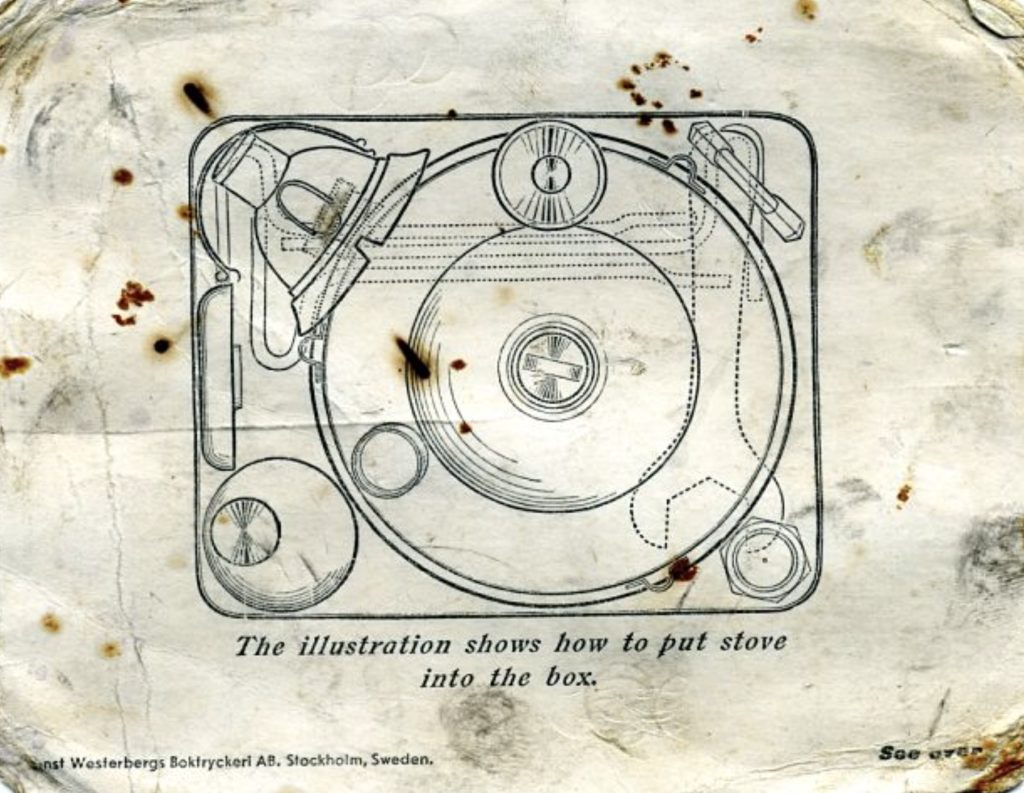

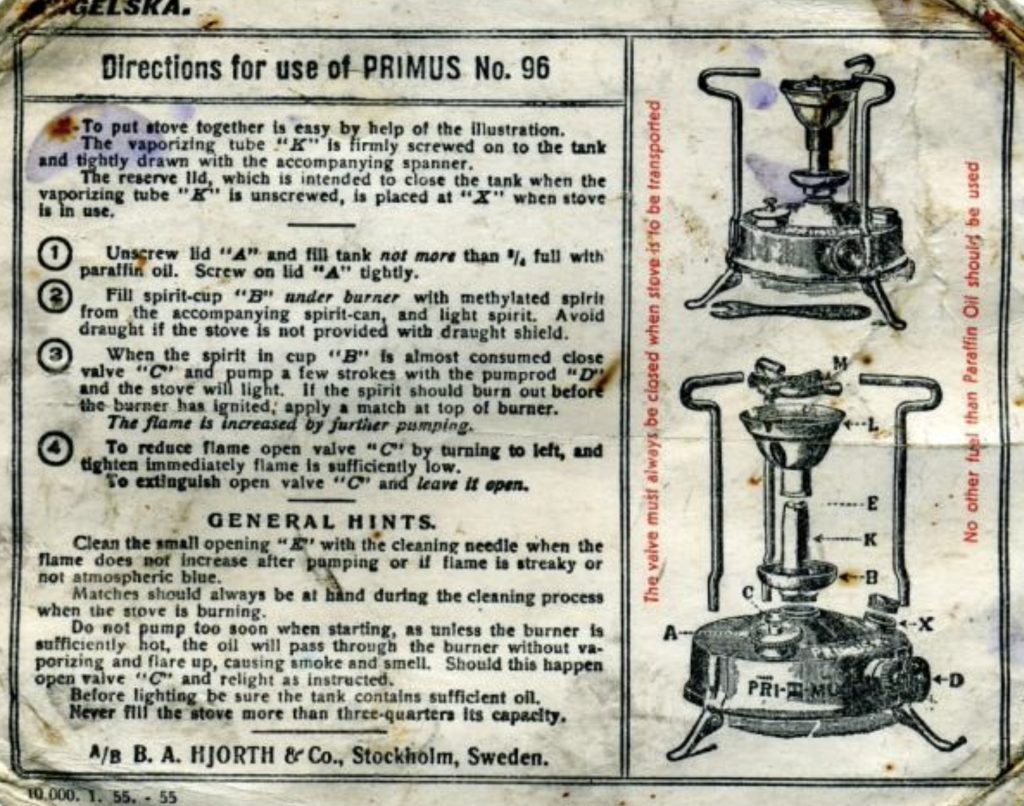

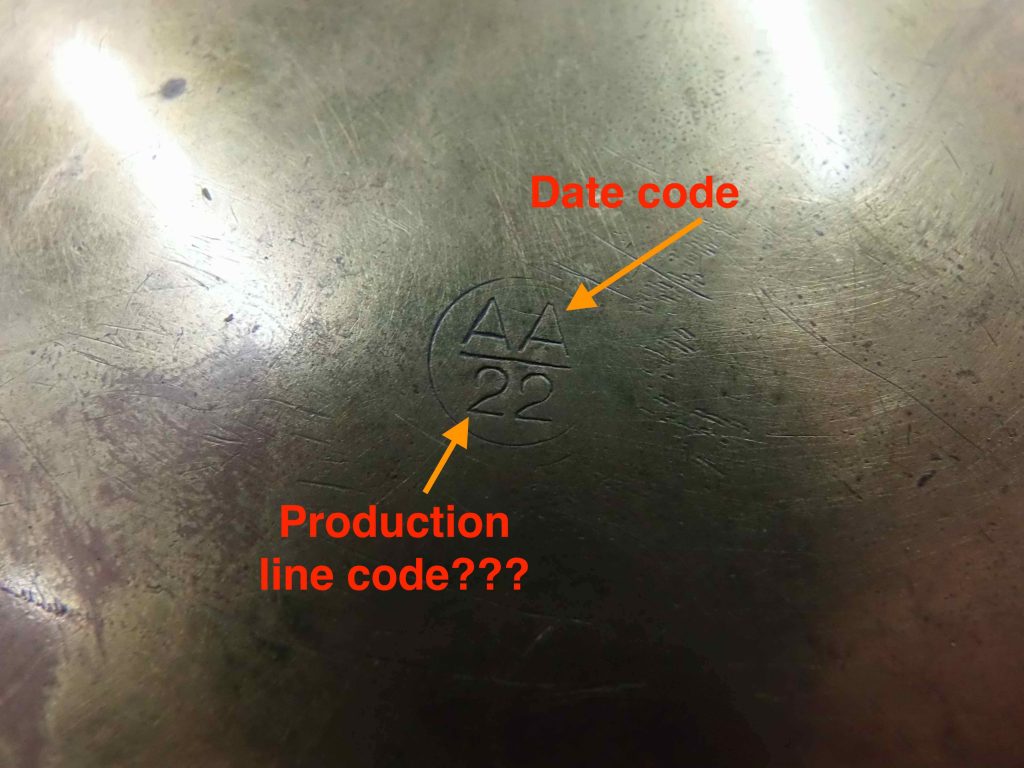

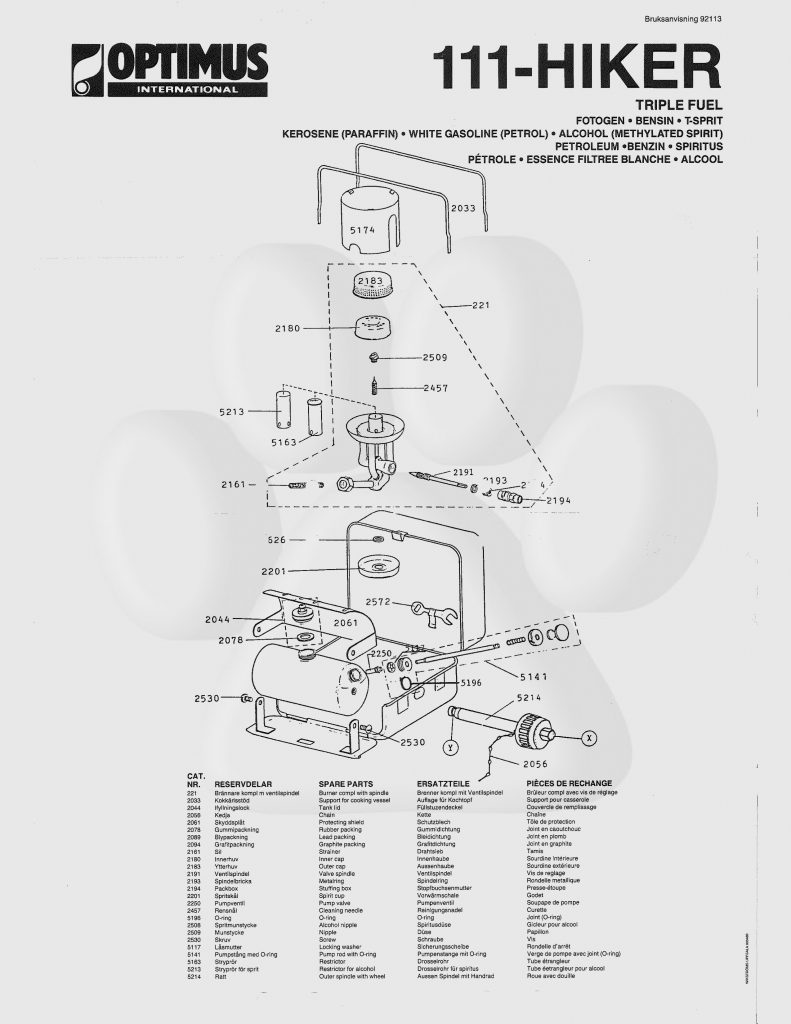

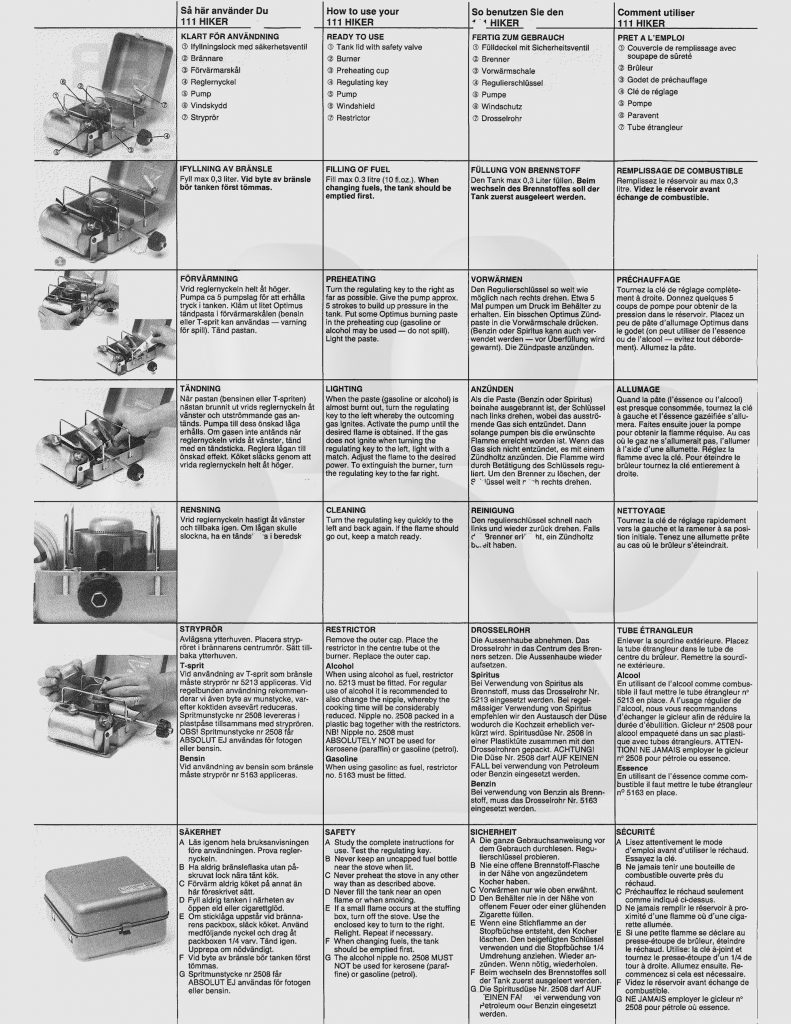

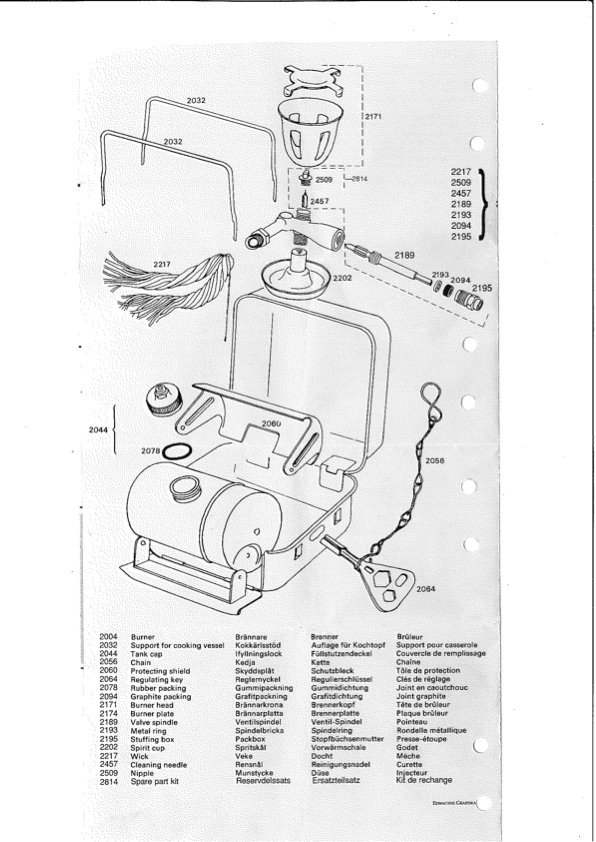

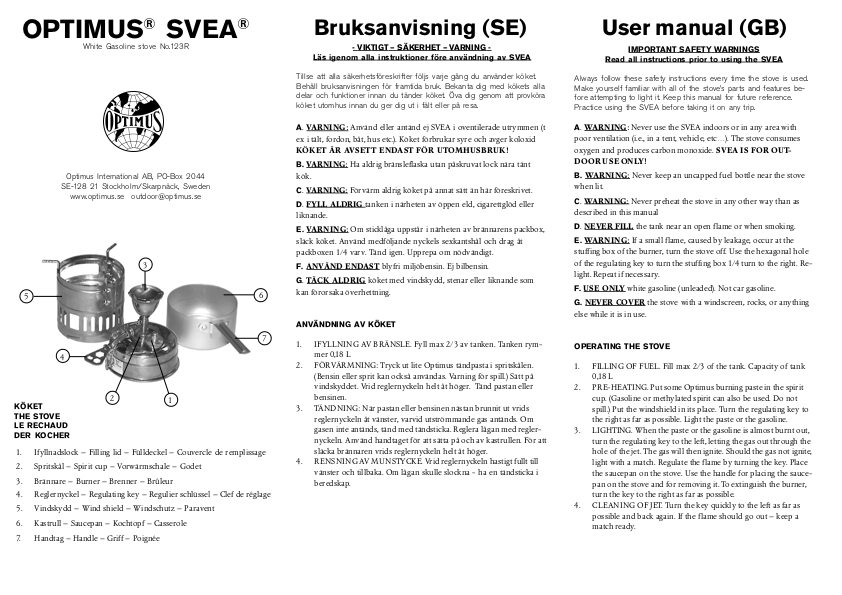

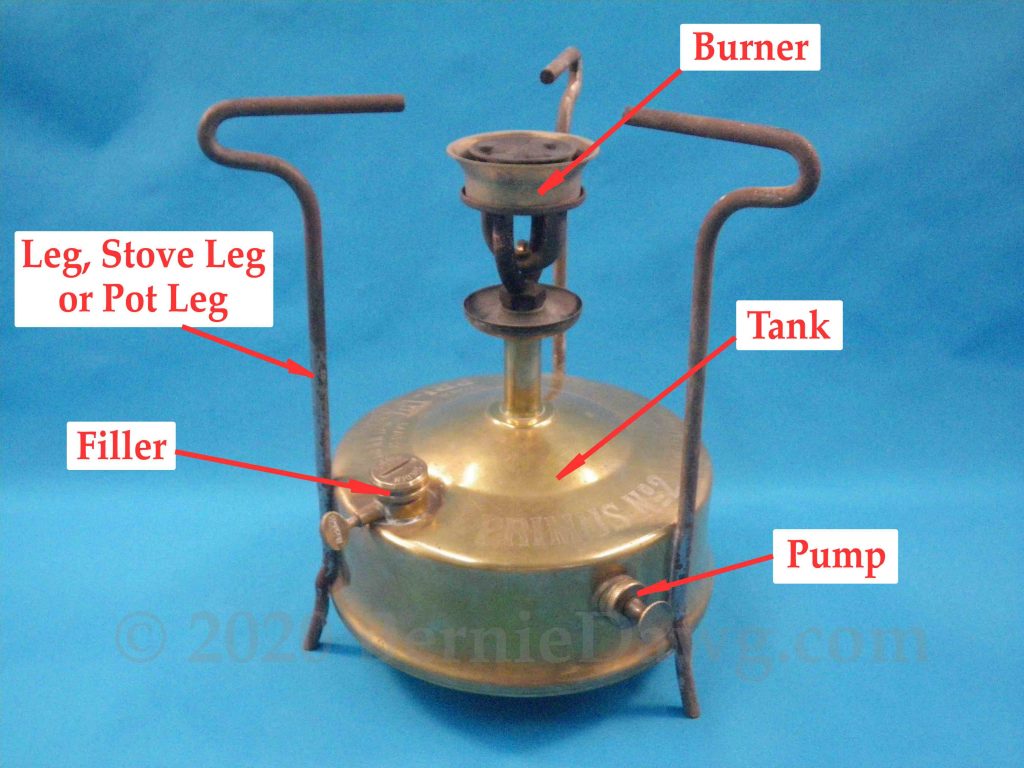

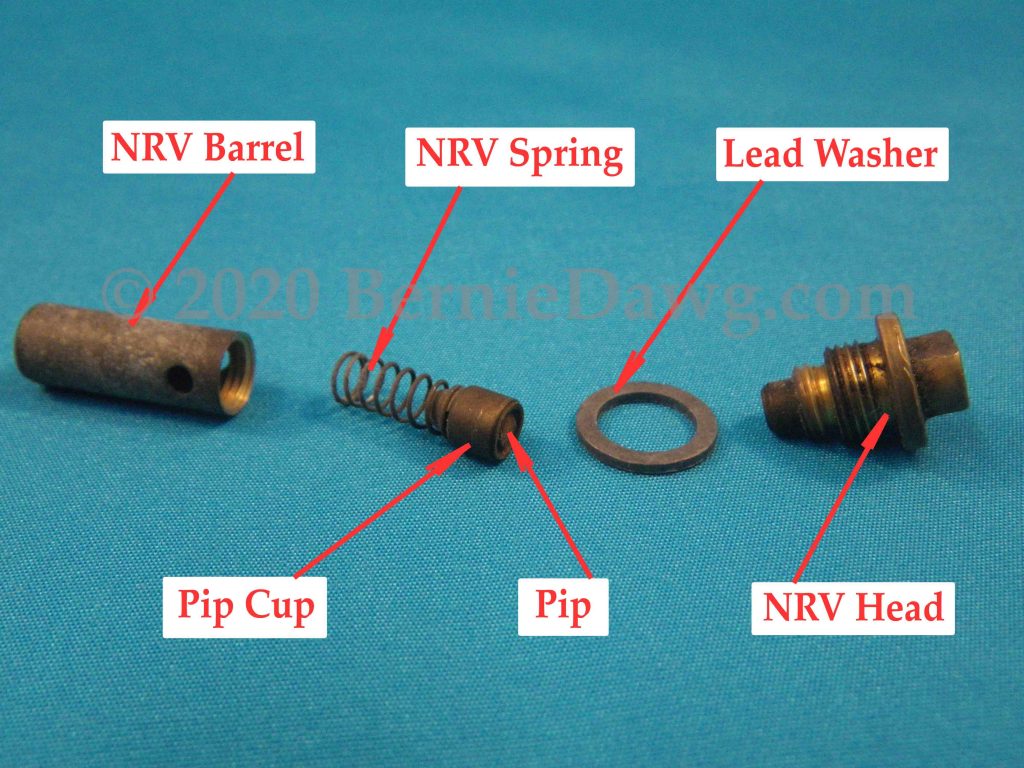

Sure. You bet. Here are some photos. All measurements in millimeters. This is a genuine Sweden-stamped and Swedish-made NRV. The dimensions are proper for the vast majority of NRVs in stoves out there. Be aware there are a few stove companies that vary from this style. Optimus, Primus, Radius, Svea/Sievert and Enders all use this style of NRV.

Length

Width

Depth

Head diameter (just for interest)

Iif you are a home hobby sort, it’s probably easiest to take a steel bolt just under the inside diameter of your pump tube, cut off the threads with a hacksaw, and then cut a slot just slightly undersized in the end of the cut-off bolt with the hacksaw. Clean the cut to exact dimensions with a file. The end will look like the end of this more polished out-of-production NRV wrench made by now-retired and out-of-sight tool maker Stu Burgess in England: (In other words, you can’t get these any more.)

If you are more of a machinist, maybe have a vertical mill, you can use a 4mm end mill with two passes in your mill and make a closed end wrench like this:

The closed-end wrench just above is an original Optimus wrench for marine stoves. The advantage of the closed end wrench is that it won’t do this in use:

I tried to make this one up from a bolt recently to fit into a specialty off-brand stove whose NRV head is down inside a pocket in the end of the pump tube. That’s a rare stove and you don’t have that concern.

The failed example I show directly above is made from a too small diameter bolt. So, try to keep your bolt as large in diameter as you can to avoid the sides bending out like this. More material gives better support.

Lastly… here are some unsolicited pointers:

- – the best way I’ve found to remove NRVs is to put the wrench upright in a vise, put the stove over the wrench, then use strong downward force on the tank to keep the wrench head on the NRV head so it doesn’t skip off the end of the wrench. I demonstrate the technique in this section of one of my YouTube videos: https://youtu.be/2LKsxIYCTko?t=226

- – tighten the NRV just slightly/gently before trying to untighten. This may help to break the brass-to-brass bond if there is no NRV head washer present

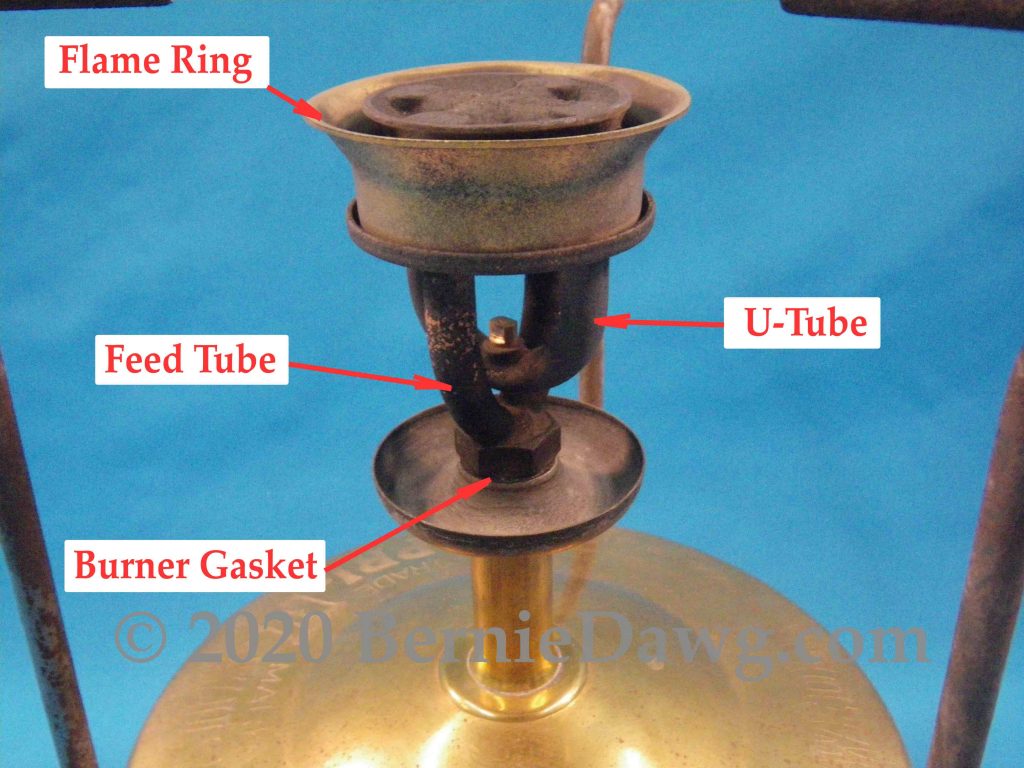

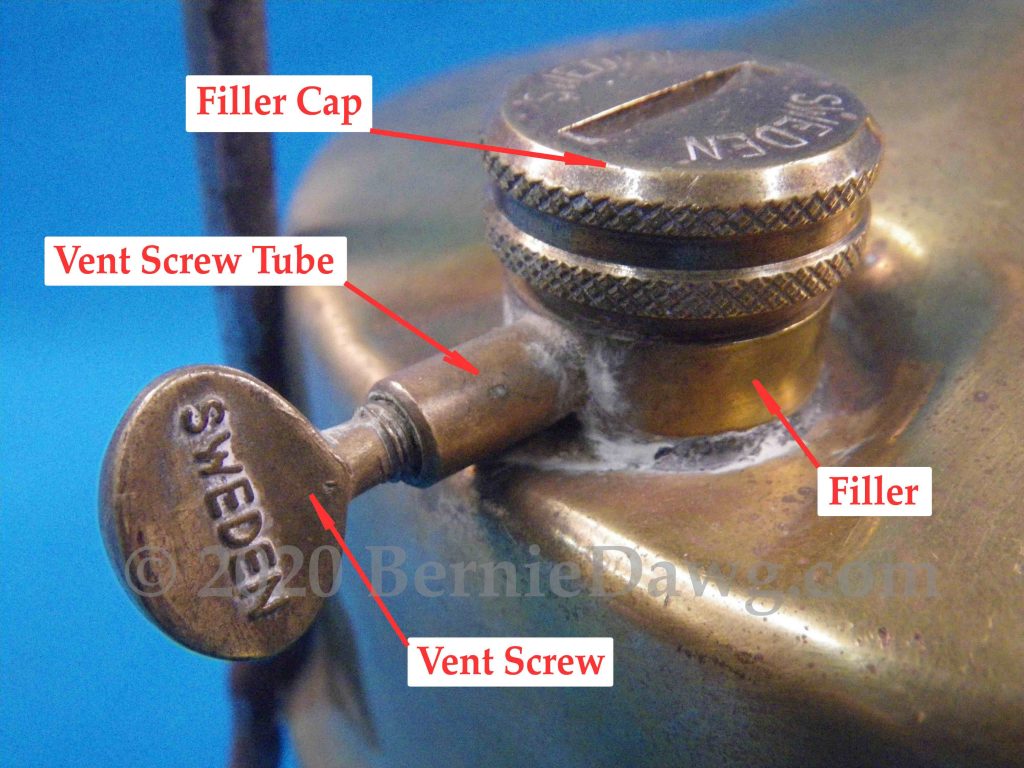

- – if you chose to use penetrants… it will do no good at all to put the penetrating oils down the pump tube. The NRV is air and liquid tight sealed inside that pump tube. Instead, use a small brush and reach inside the tank through the fuel filler to apply penetrant to the outsides of the pump tube where it will run down the tube and get into the exposed threads of the NRV that are hanging out at the end of the threaded pump tube end block. That is where you want penetrating oils to assist.

Hope that helps. Good luck!

BD